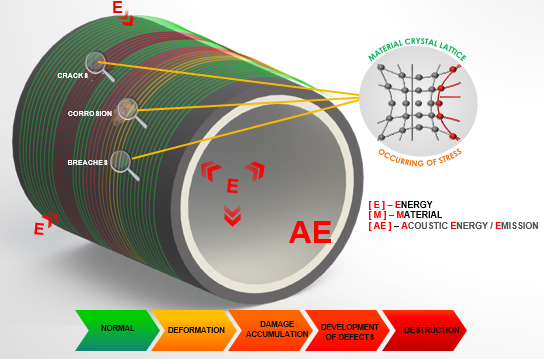

VSSI provide Niche online inspection services utilising our state of the art Hybrid Accoustics Technology (HAT).

HAT technology is used to identify Active Defects on Tanks, Pipelines, Boilers, Flare Stacks Separators etc while the asset is in Service.

HAT is used to provide the asset owner data about the state of the asset before having to shutdown their assets for intrusive inspection to identify defects that could render the asset being out of Specification and regulation.

HAT complies to international standards of inline inspection of Static Assets.

☼HATs reduce the volume and labour intensity of monitoring, repair and tests

☼HATs simplify the preparation of Standards and Procedures for maintenance program.

☼HATs is cost effective in the context of total plant inspection, maintenance and repair cost.

☼HATs monitoring/data gathering can be conducted without plant shutdown or production interruption.

☼HATs provides real time data acquisition which can be utilized for assessment up to Fitness for Service (FFS).

☼HATs requires minimal modification to the diagnosed candidate and operation parameters are maintained during monitoring/data gathering.

☼HATs is not affected by variable diameter, fittings and flanges, limited accessibility and can be applied in most climatic conditions.

Some of our clients include :

Occidental of Oman(OXY) Petronas Carigali

Oman Refinery and Petrochemical industry Co.(ORPIC) SABIC

Shell Brunei Oman Gas Company(OGC)